Home | Contact us|

Home | Contact us|  Home | Contact us|

Home | Contact us|

Micro-Simulation Technology has received a purchase order from the International Atomic Energy Agency (IAEA) to expand its PCTRAN simulation software to the Russian-designed VVER1000. It will soon be delivered to the Vietnam Agency for Radiation and Nuclear Safety (VARANS) in Hanoi, Vietnam.

Since the early V320 models built and operating in Russia and a number of east European countries, there are improved AES90 and 91 models constructed in Iran, India and China. The latest AES92 meets European Design Criteria for the so-called “Generation III” criteria with improved passive cooling systems and debris collating devise. It will be the main model for future construction. For educational purpose, the PCTRAN VVER1000 is not modeled after any specific one of the above. Instead it is “generic” to accommodate all by providing various plant input data sets so that the same software could simulate all.

New VVER-1200 (AES91 or 2006 Model 392M)

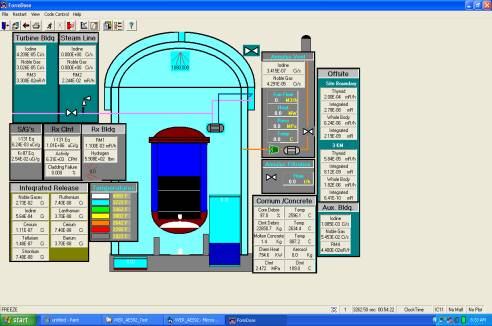

In the NSSS mimic below, a single loop with the pressurizer is modeled separately from the other three loops lumped together. Plant data parameters controlled by the users would define the model to represent a specific plant.

There are full control systems for the reactor, pressurizer and steam generators. The plant can be controlled either by hand or automatic. In automatic it can be either turbine-driven or reactor driven. For emergency core cooling, Model V320 is provided only with high and low pressure nitrogen-filled tanks. Later AES series have added high-pressure injection pumps. Here in PCTRAN we provide both in the left side panels in the mimic. So the same software can simulate either plant simply by activating/disabling certain systems. The plant size and power between each model are also different.

There is a bubble condenser receiving vapor discharge from the pressurizer, reactor head and SG vents. When the condenser pressure exceeds its designed set point, a protective membrane breaks. The containment of AES92 is quite different from V320. The picture below shows double containment, passive heat removal, vent and debris catcher systems.

Operation is interactive in Windows graphic user interface. Selection of transient event is menu-driven that covers:

A number of operational transients have been analyzed to show the plant’s control and protection system response without causing a reactor scram. For operational transients we have successfully simulated the following cases:

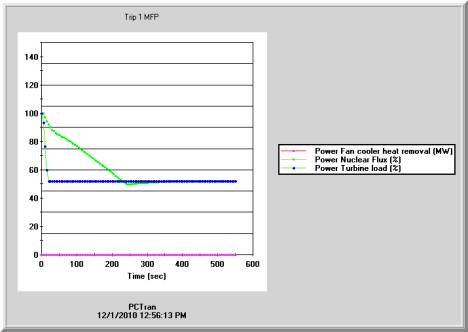

1. Loss One of Two SG Feed Pumps

At loss of two feed pumps, the load is run back to 52%. The transient is smooth as expected.

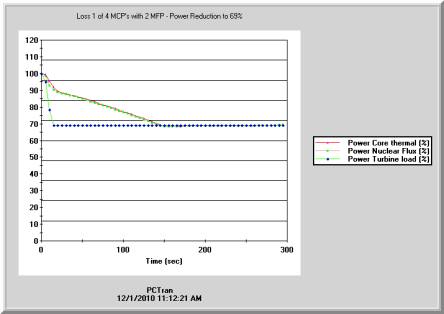

2. Trip One of Four Operating MCP’s

Upon loss of one of four Operating MCP’s and 2 FWP in operation, power is runback to 69%.

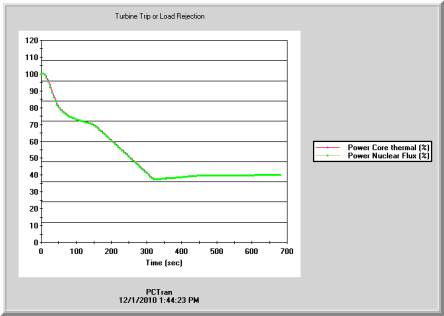

A turbine trip or load rejection will cause automatic power runback to 40% without a reactor trip.

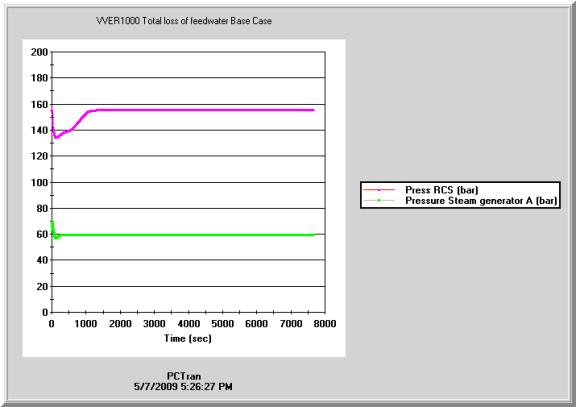

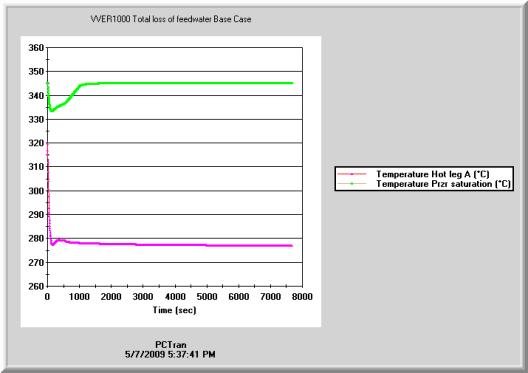

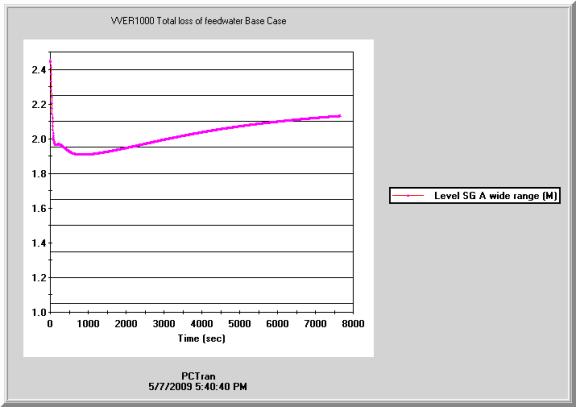

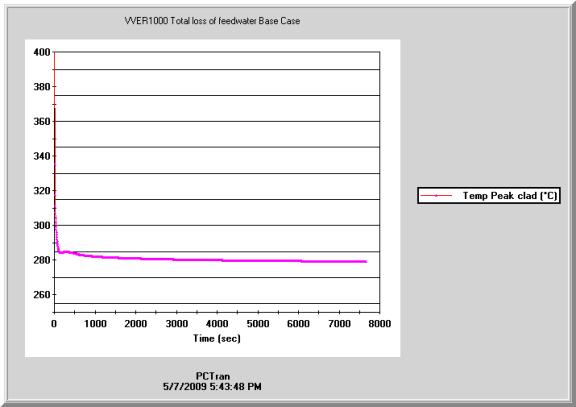

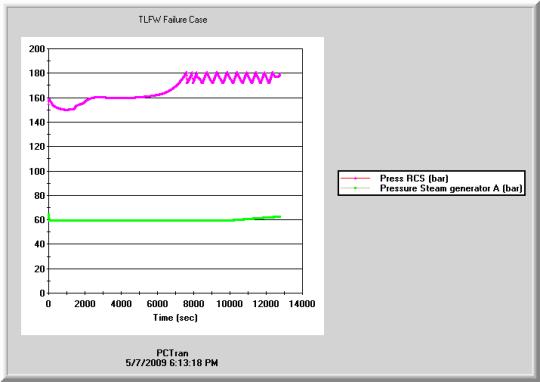

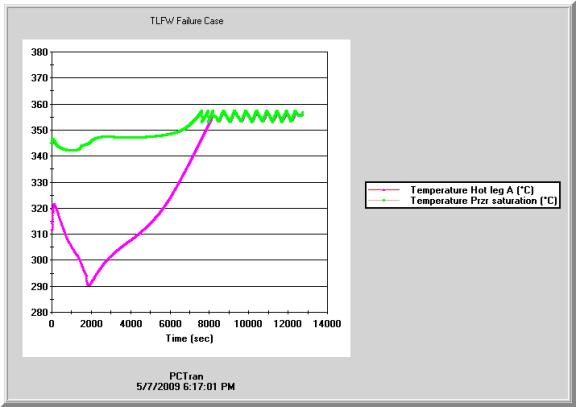

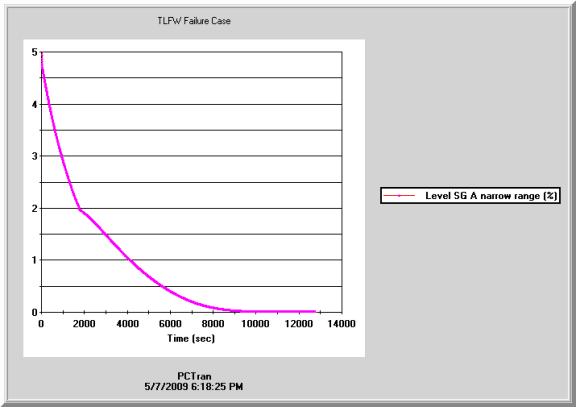

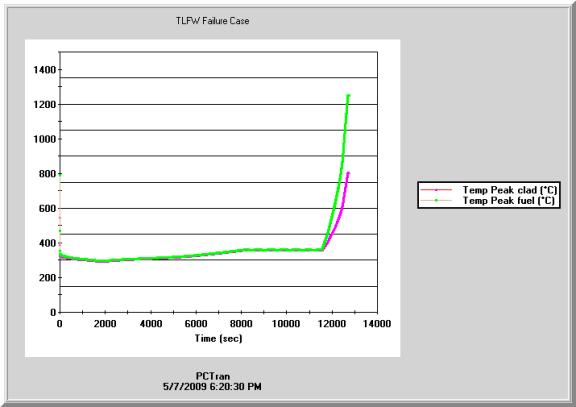

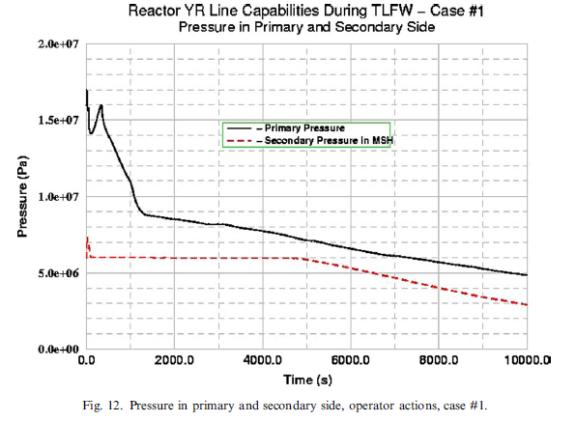

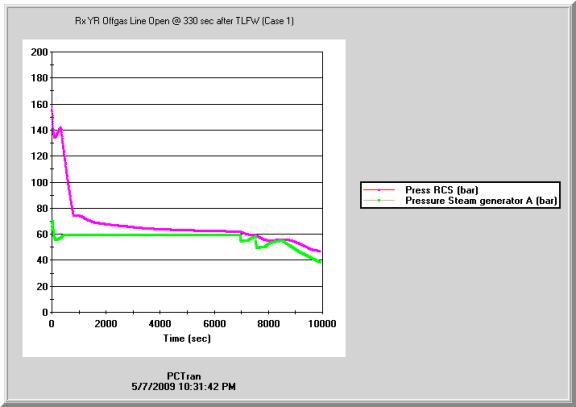

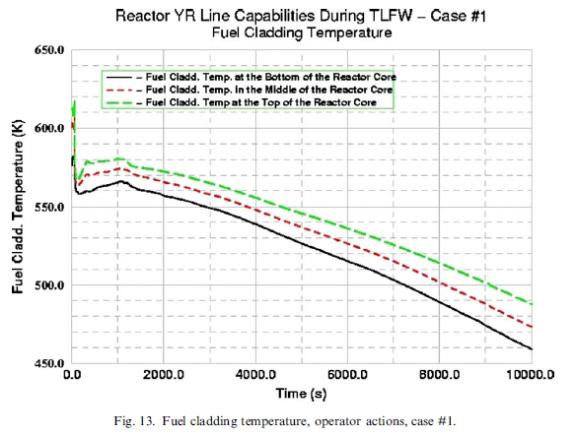

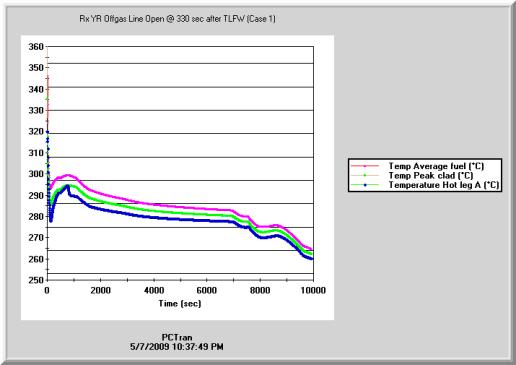

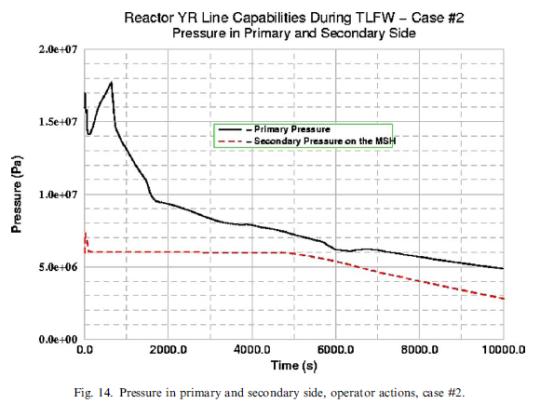

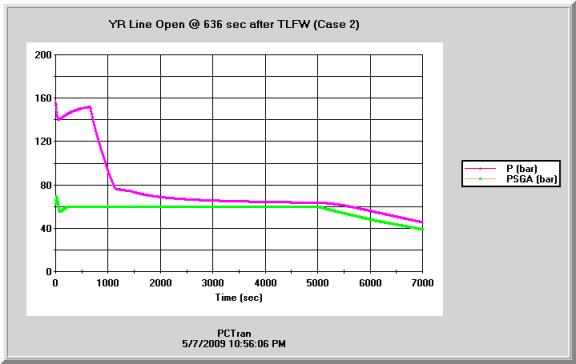

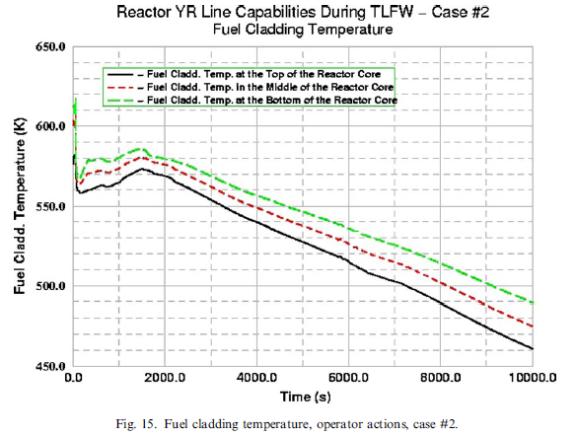

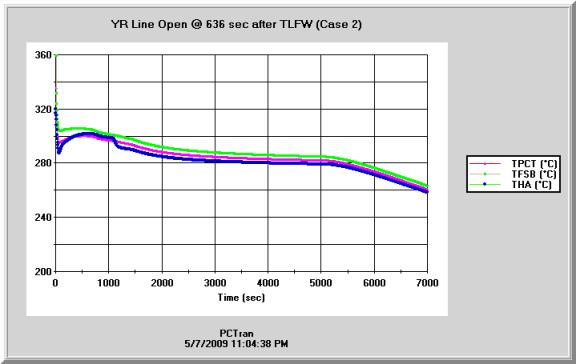

Note in the PCTRAN mimic above the reactor vessel head there is a YR off-gas vent line. After a total loss of feedwater (TLFW) event, the Bulgarian study concluded that opening the YR line prior to the reactor coolant saturation could prevent core damage. In the paper there are:

We have successfully benchmarked these four cases in high fidelity. The phenomena of SG inventory depletion, primary coolant over-heat to saturation, PORV lifts and cycling, RC inventory depletion through the PORV, venting via the YR line, etc. were not only reproduced, but also the key transient variables in numerical accuracy.

It proves PCTRAN/VVER-1000 to be a highly sophisticated simulation tool for severe accidents.

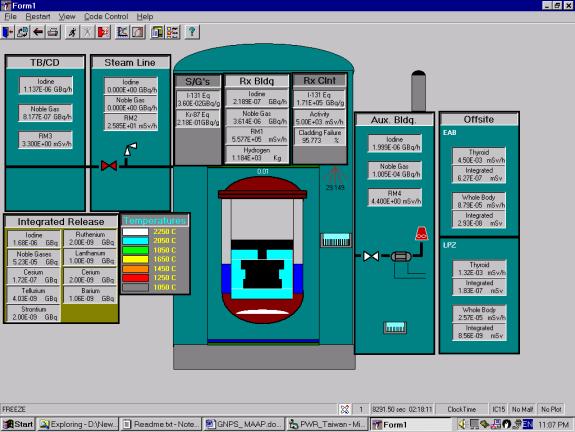

Upon successful installation of the PCTRAN PWR Severe Accident Module, clicking at “Run” will start a run. For LOCA without ECCS will lead to core melt and containment failure. Click “View” and “Dose will give you another view of the core and dose release configuration.

By going into “Restart” and choose other “Initial Conditions” you may observe the plant at various stages of degraded conditions. There is even one for hydrogen burn. You may also activate any mitigation devices such as ECCS, PORV, containment spray, SG PORV, AFW, etc. and witness their impact and consequences.

For the SAMG event, both trains of ECCS were assumed to run for maximum rate of depletion of the RWST. At about 1000 seconds after the double-ended break, recirculation from the sump was assumed to be lost. The core subsequently became uncovered, melt, collapsed and eventually debris penetrated the vessel. The degraded core mimic is shown below: