Home | Contact us|

Home | Contact us| Home | Contact us|

Home | Contact us|

By winning the major reactor contracts from Jordan and UAE, the Koreans have successfully landed their first export projects. It weighs significantly to their bid for power plant export to the Middle East, North Africa and Southeast Asia.

One thing for certain countries going to nuclear power for the first time would like evaluate ALL technologies first hand. Many have approached us to get a fleet of PCTRAN models to understand everyone’s dynamic performance. The low-cost simulator suite enables their technical staff have hands-on experience in transient operation. In addition to Western PWR, BWR and Russian PWR (VVER), now we also provide KSNP1000 and APR1400. Evolving out of the former Combustion Engineering System 80, we have over 10-years experience with C-E plants Fort Calhoun, Ste Lucie and Calvert Cliffs. In particular for Calvert the current PSA update of success criteria determination is conducted by using our PCTRAN model. It has been verified, peer reviewed and formally documented as part of license basis docket with the regulatory agency.

KSNP and its later OPR (Optimized Power Reactor) and APR inherit C-E System80+ design of two hot legs and 4 cold legs with two large steam generators. For total loss of feedwater event, a Safety Depressurization System (SDS) with two trains of remote manual operable valves to dischare the primary steam to the containment. High Pressure Injection from the Safety Injection Tanks is then pumped into the core to keep it cooled. Free Download

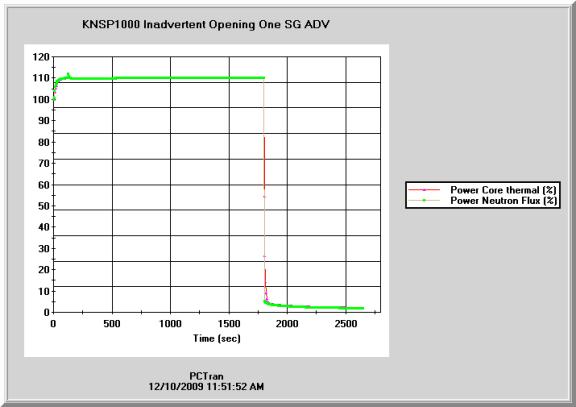

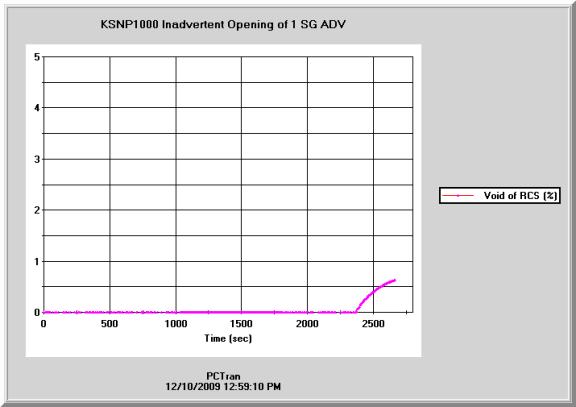

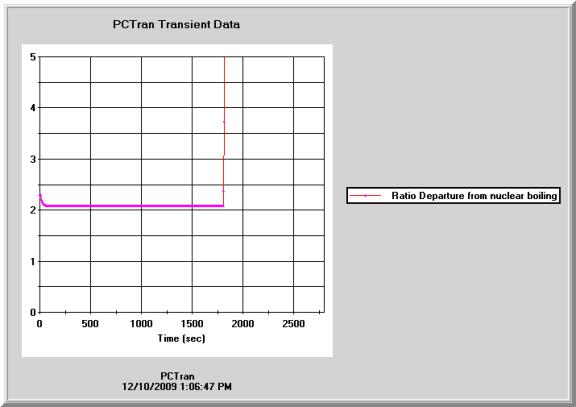

1. Inadvertent Opening of Steam Generator Atmospheric Dump Valve (IOSGADV)

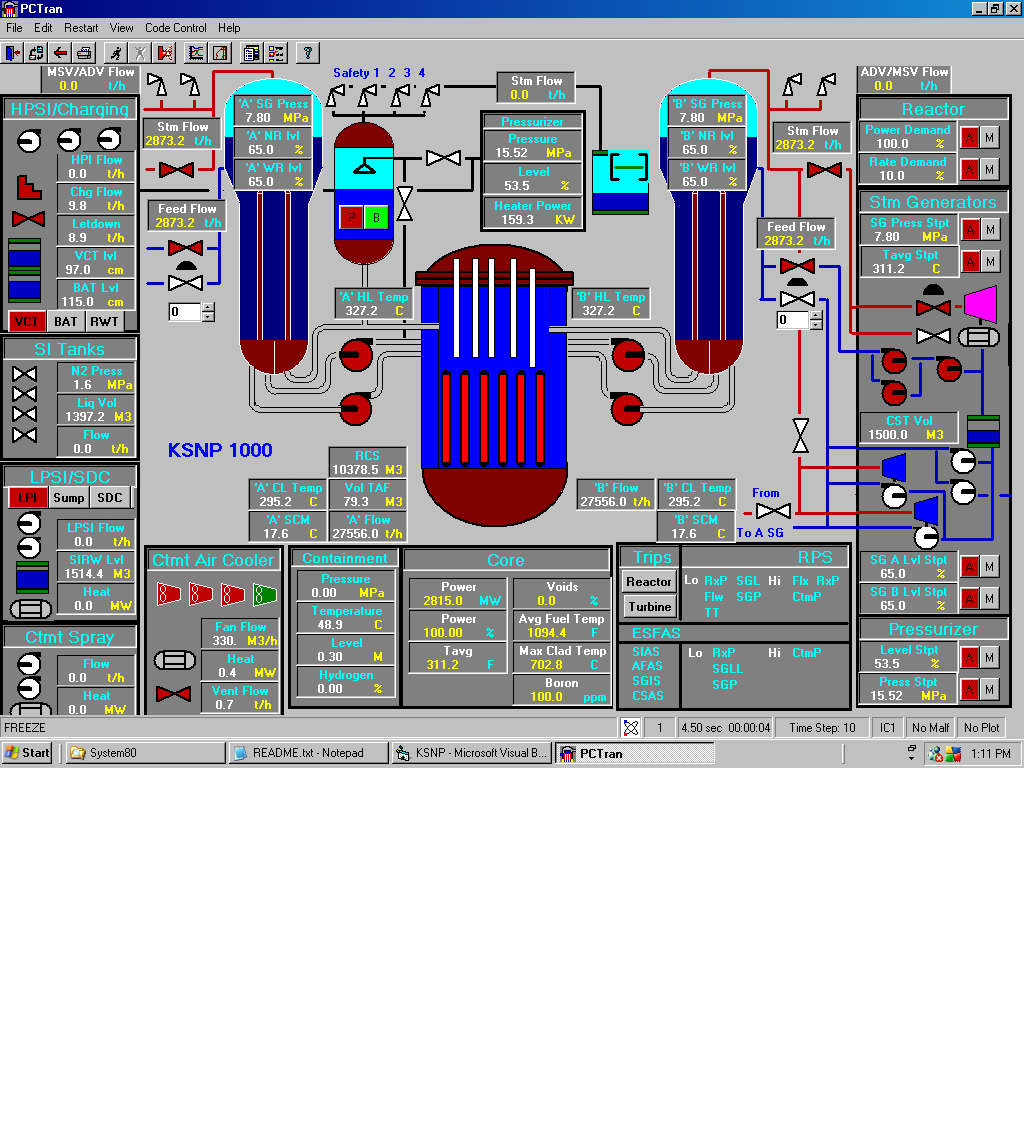

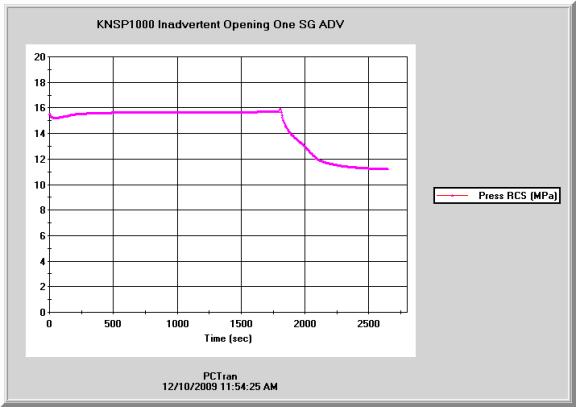

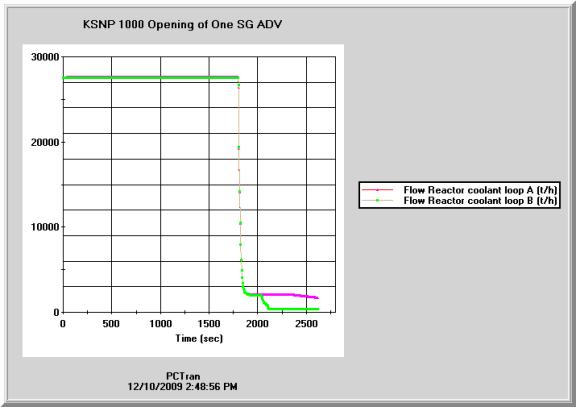

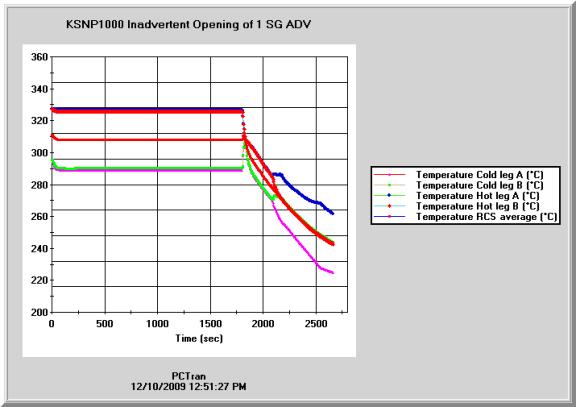

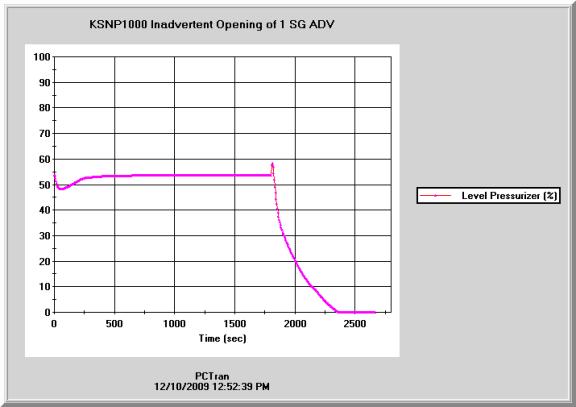

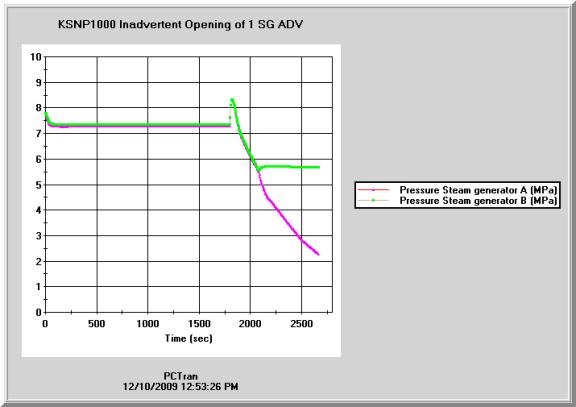

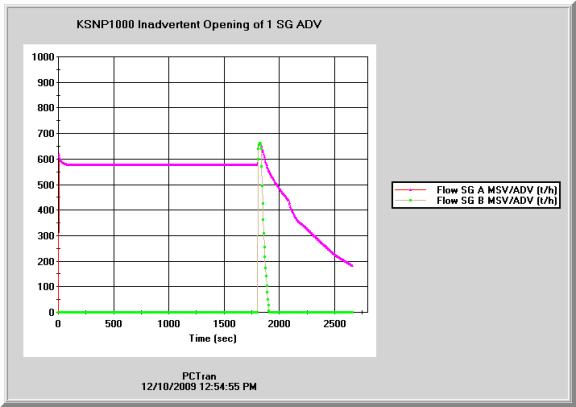

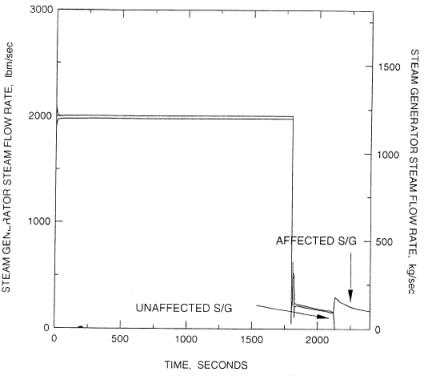

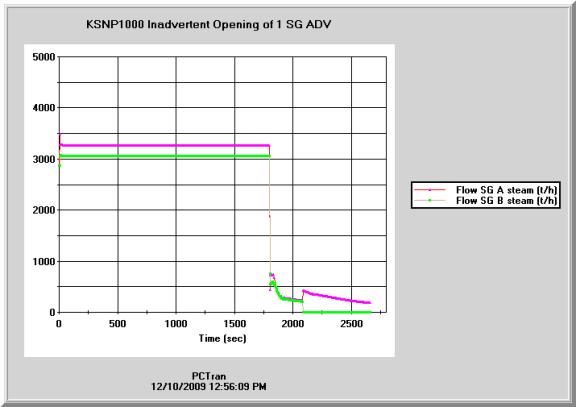

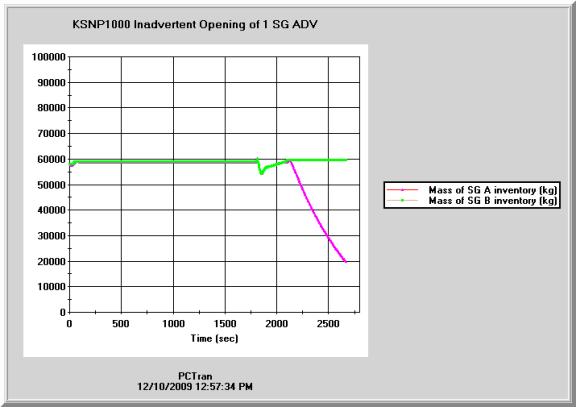

PCTRAN KSN/P1000 is modeled with full power at 2815 MWt and Tavg at 311ºC. One SG ADV opening has flow rate about 400 lb/s or 645 t/hr at steam pressure of 7.8 MPa.

TABLE 15.1.4-2

SEQUENCE OF EVENTS FOR FULL POWER

INADVERTENT OPENING OF A STEAM GENERATOR

ATMOSPHERIC DUMP VALVE (IOSGADV)

Setpoint

Time (sec) Event or Value

0.0 One atmospheric dump valve opens fully --

100.0 Minimum transient DNBR ³ 1.30

1800.0 Manual trip --

1800.1 Trip Breakers Open --

1803.1 Loss of Offsite power/RCPs begin to coastdown --

1808 Main steam safety valves open, psia 1277

(kg/cm2A) (89.77)

1822 Main steam safety valves close, psia 1213

(kg/cm2A) (85.27)

2120.35 Steam generator pressure reaches main steam 851

isolation signal (MSIS) analysis setpoint, (59.83)

psia (kg/cm2A)

2126.5 MSIVs close completely --

2131.5 MFIVs close completely --

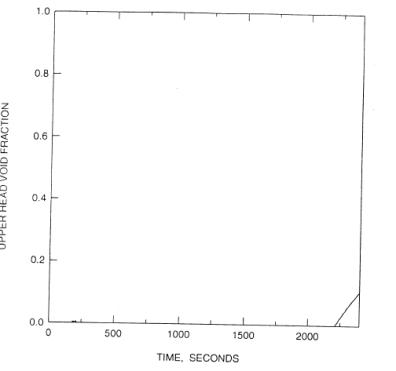

2219 Voids begin to form in RV upper head --

3000 Operator manually closes ADV --

3600 Operator initiates plant cooldown --

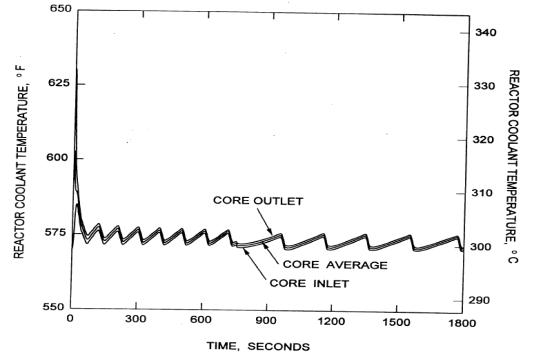

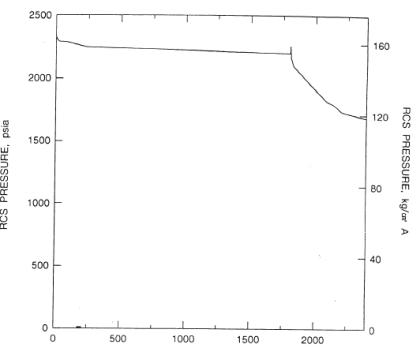

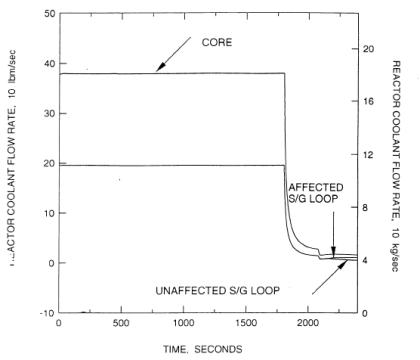

Note, the scale at right hand side in C is wrong!

(Right hand legend should be Kg instead of lbm)

Benchmark of the following Study was conducted:

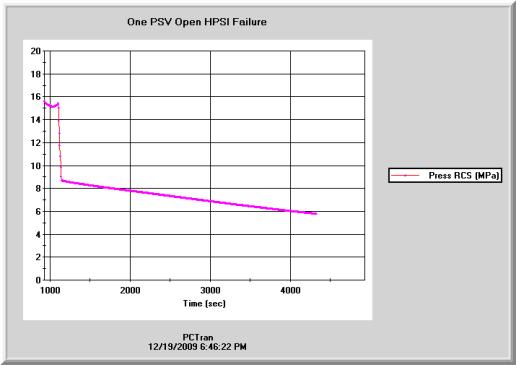

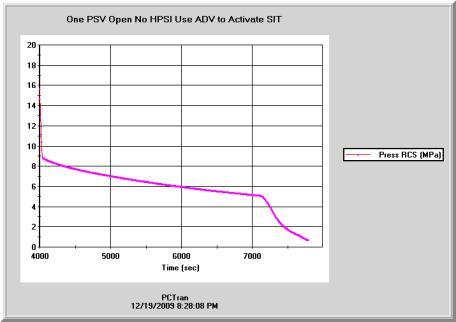

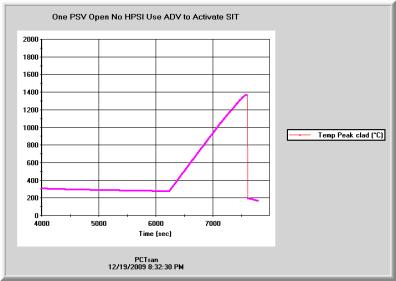

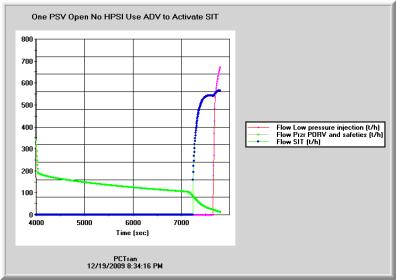

PCTRAN was initiated from a condition of 1.4% decay heat post-trip condition. One PSV was forced to open and stuck at the open position. The reactor coolant pressure would depressurize rapidly and initiate the HPSI. One pump is sufficient to keep the core covered without damage. This was done in the first RELAP case and also verified with PCTRAN. The second one assumes no HPSI available. It is benchmarked here using PCTRAN:

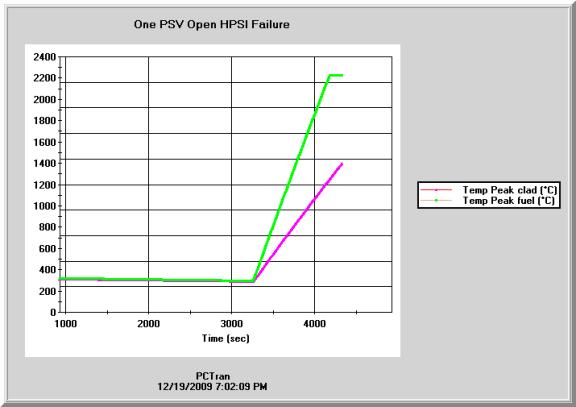

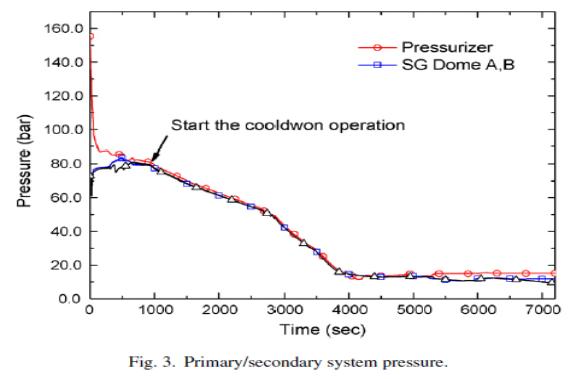

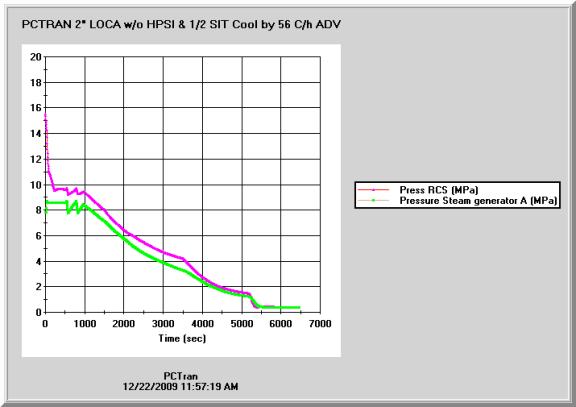

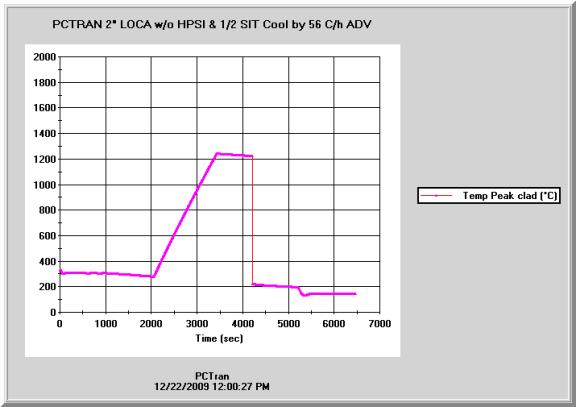

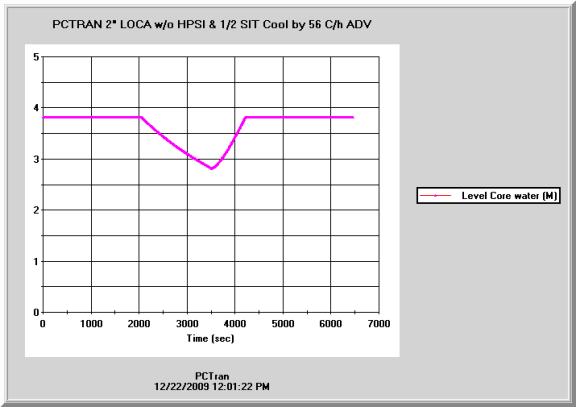

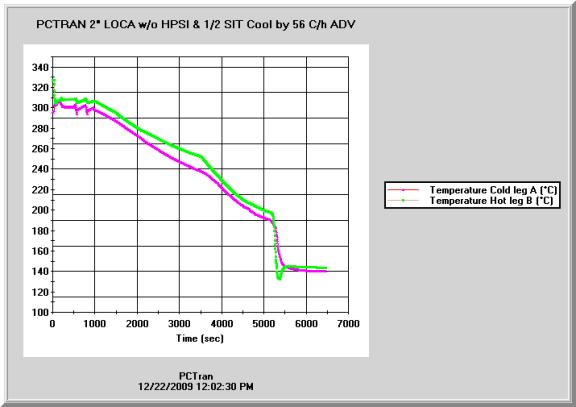

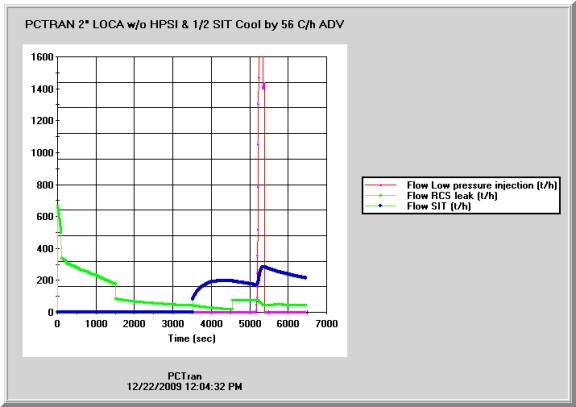

The second case used ADV to depressurize the SG secondary. This accelerates the RCS primary depressurization to reach the SIT initiation set point (4.1 MPa) in the event of no HPSI. Note PCTRAN’s initial condition is 4000 seconds after reactor trip so that the decay heat (1.5%) matches closely with the RELAP case’s initial power (1.4%). In the PCTRAN run, ADV’s of both SG sides are opened about 3,000 seconds after event initiation.

PCTRAN confirms that by opening the ADV’s to accelerate cooldown, the extent of core heatup is limited. Both SIT and LPSI are initiated that refloods the core and cools it down.

3. Small Break LOCA Without HPSI Operator Action Benchmark

PCTRAN was run against the KAERI case below:

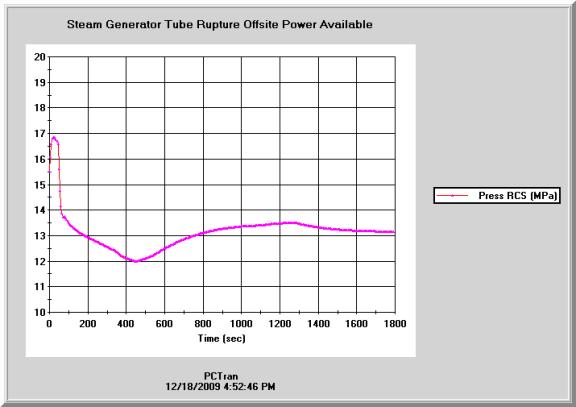

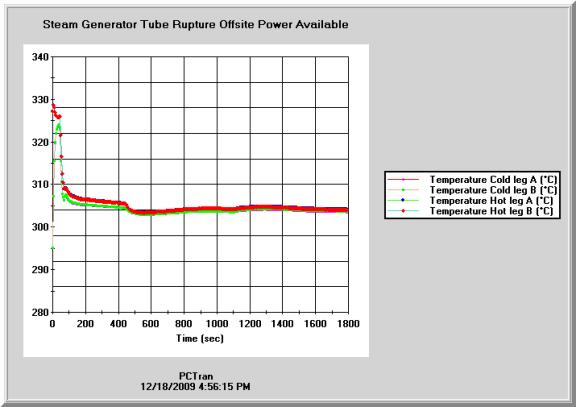

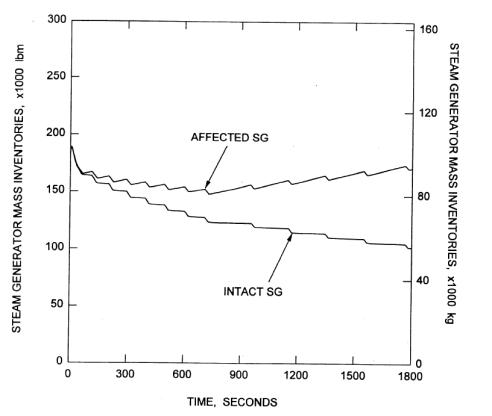

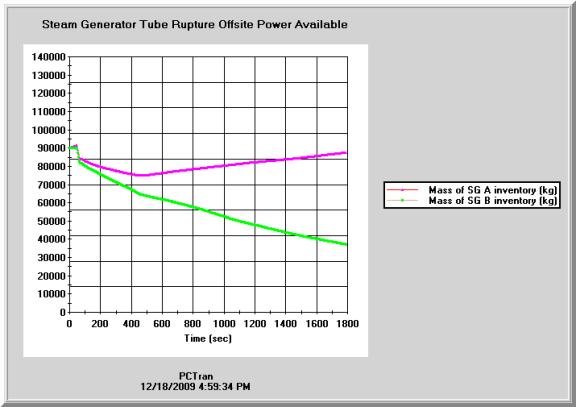

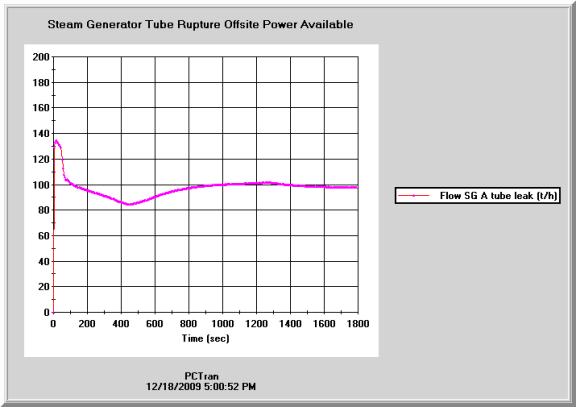

UCN3 & 4 FSAR TABLE 15.6.3-1

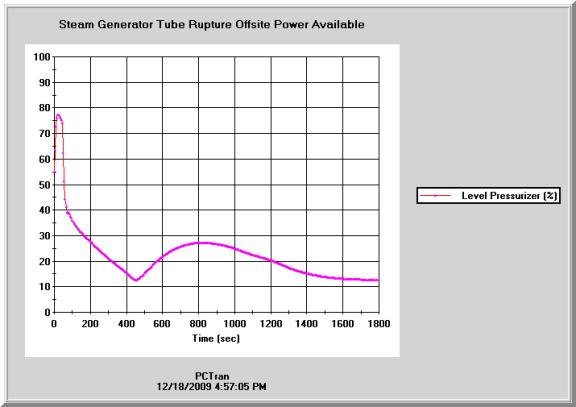

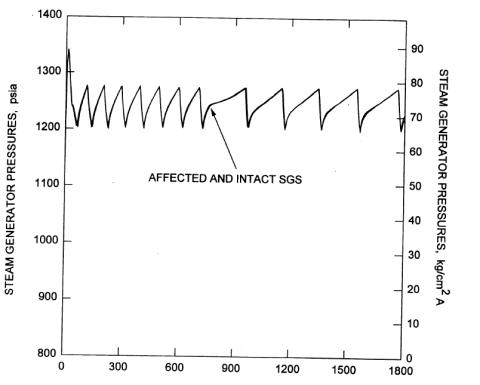

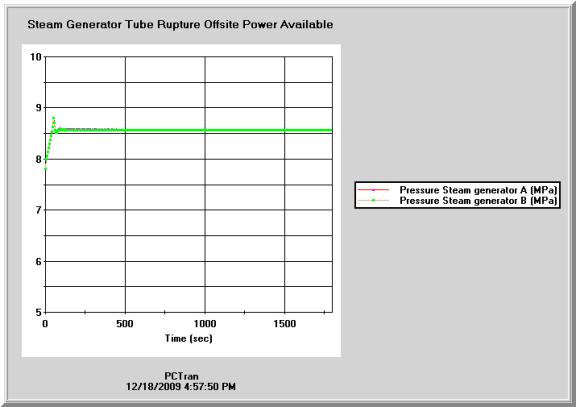

SEQUENCE OF EVENTS FOR THE STEAM GENERATOR TUBE

RUPTURE WITHOUT A LOSS-OF-OFFSITE POWER

Time Setpoint

(sec) Event or Value

0.0 Tube rupture occurs --

0.0 SG level reaches reactor trip 95

and MSIS setpoint, %NR

0.45 High steam-generator level --

trip signal generated

0.55 Trip breaker open --

0.55 Turbine trip; stop valves closed --

0.55 MSIS generated on high steam- --

generator level

4.4 Main steam safety valves open, 1277

psia (kg/cm²A) (89.8)

5.55 Main steam isolation valves --

close completely

11.95 Maximum steam generator pressure, 1341

psia (kg/cm²A) (94.3)

15.95 Backup heaters energized, psia 2275

(kg/cm²A) (160)

91.8 Letdown control valve throttled -2.0

back to minimum flow, feet (meters) (-0.61)

below program level

TABLE 15.6.3-1 (Sh. 2 of 2)

Time Setpoint

(sec) Event or Value

211 Pressurizer heaters deenergized 414

due to low pressurizer liquid (11.7)

volume, ft3(m3)

214 Third charging pump started, -5.73

feet (meters) below program level (-1.75)

719.4 Pressurizer pressure reaches 1705

safety injection actuation (119.9)

signal (SIAS) analysis setpoint,

psia (kg/cm²A)

750.55 Safety injection flow initiated --

1800 Operator isolates the damaged --

steam generator and initiates

plant cooldwon at 100°F/hr

(55.6°C/hr) for the 1.5-hour

time period

28,800 Shutdown cooling entry conditions 410/350

are assumed to be reached, RCS (28.82/176.7)

pressure/RCS temperature,

psia/°F (kg/cm²A/°C)

TABLE 15.6.3-2

ASSUMPTIONS AND INITIAL CONDITIONS FOR THE STEAM GENERATOR

TUBE RUPTURE WITHOUT A LOSS-OF-OFFSITE POWER

Parameter Assumed Value

Core Power Level, MWt 2871.3

Core Inlet Coolant Temperature, °F (°C) 570 (298.89)

Initial Pressurizer Pressure, psia (kg/cm²A) 2325 (163.45)

Core Mass Flow Rate, 106 lbm/hr (kg/hr) 111.16 (50.4)

One Pin Integrated Radial Peaking Factor,

with Uncertainty 1.7204

Steam-Generator Pressure, psia (kg/cm²A) 1148 (80.7)

Moderator Temperature Coefficient, 10-4 Δρ/°F 0.0

Doppler Coefficient Multiplier 1.0

CEA Worth at Trip, % (most reactive CEA -9.0

fully withdrawn)

Steam-Generator Water Level, %NR 95